Palletizing machines have seen rapid development in the last few years. In December 2005, the Automated Packaging Machinery Market outlined the global value of palletizing equipment to be USD 3.2 billion by 2025, with a CAGR of 5.3% over the years. Through enhancing operational efficiency and cost-effectiveness, it enables companies to streamline their supply chain processes; as businesses try to serve the increasing demand for e-commerce and just-in-time model inventory, the evolution of stacking palletizer machines becomes a key aspect in remaining competitive in the global market.

The stacking palletizer machine's uses transcend the realm of automation; increasingly, they are becoming the very sinews and consider the resiliency of supply chains on a worldwide scale. With the current disruptions brought about by the pandemic- COVID-19 being one such instance-companies are pouring money into advanced palletizing technologies to ensure their ability to respond to sudden changes in market requirements. According to research conducted by Robotics and Automation in Logistics, 65% of logistics companies plan upgrades for their current automation setup, with stacking palletizer machines at the forefront. On this note, as our path follows through the evolution of this technology, one thing is clear: that the very innovations implying productivity transformation have, conversely, begun to redefine the very strategies along which global supply chains are being conducted.

Since about the year 2000, the evolution of stacking palletizer machine technology has greatly altered the workings of global supply chains. Historically, palletizers transitioned from manual to automated operations under the pressure of efficiency and low labor costs. The early innovations in the first half of the 20th century revolved mainly around mechanical automation, providing the foundation for modern technological advancements. The present-day stacking and palletizing applications are turning out smarter owing to advanced robotics and intelligent technologies, augmented by artificial intelligence for an intelligent sorting and stacking process. The latest trends highlight the current competitive environment with companies like Nolu股份, 机器人, and 昆船智能 driving innovations. The launch of new AI-based stacking machines by 旷视 confirms industry efforts to improve operational efficiency and accuracy. Conferences such as the "2020 Global Logistics Technology Conference" have showcased these improvements, asserting the key role of automation in worldwide supply chains. The outlook for stacking palletizer machine technology remains bright, with a fairly large market scale anticipated. While advanced technologies thus simplify the logistics process, they also enable companies to respond rapidly to the increasingly dynamic global supply chain environment. Each new generation of stacking palletizer technology will continue to contribute further to the future of logistics and operational excellence.

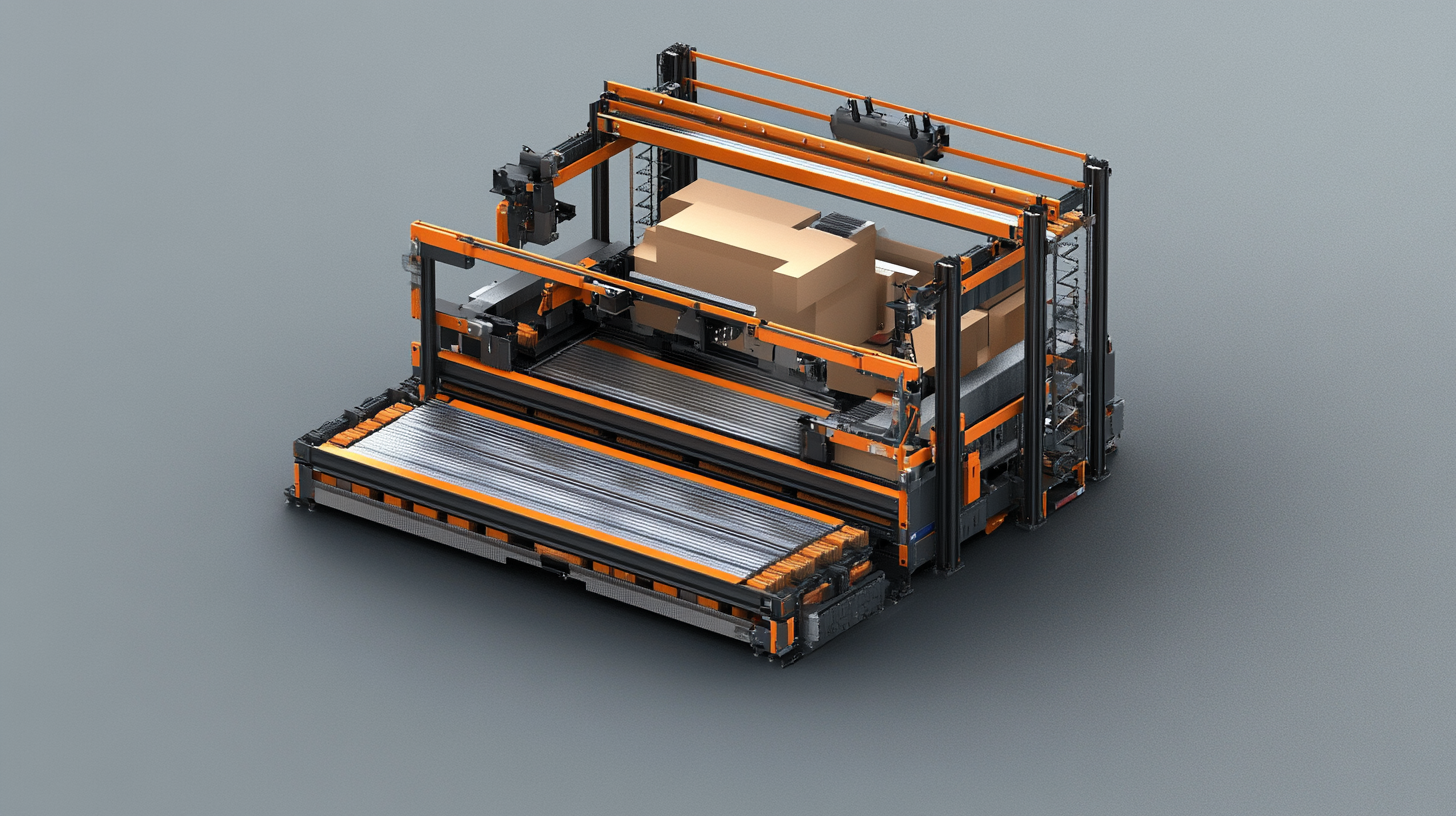

Changes in technology for stacking palletizers will shape global supply chains. Technologies such as integrating AI, IoT, and robotic automation allow companies to be agile and efficient in their logistics operation. Modern palletizers, amongst other benefits, can thus equally handle multiple product types, space optimization, and waste reduction in warehouses. These newly adopted concepts are vital for businesses to meet the fast-growing demand on faster and reliable distribution.

Beside the advancement of these technologies, major companies' initiatives, such as those of the State Grid Corporation of China, offer a perspective view on digitalizing the so-called traditional industries. The commitment towards green and modern digital upgrades shows that a greater transformation is underway whereby supply chains are being transformed into resilient and secure systems altogether. Such aims encourage the use of technologies such as 5G for a seamless flow of information and resources, which can assure the integrity of the supply chain against any disruption.

These innovations in stacking palletizer machines align perfectly with the goals of enhancing supply chain robustness. As industries incorporate increasing levels of automation and data analytics, their operational flexibility and responsiveness to change are vastly enhanced. The synergy not only generates an increase in productivity but also creates the means for sustainable practices that strongly support the global trend of enabling environmentally friendly supply chain solutions.

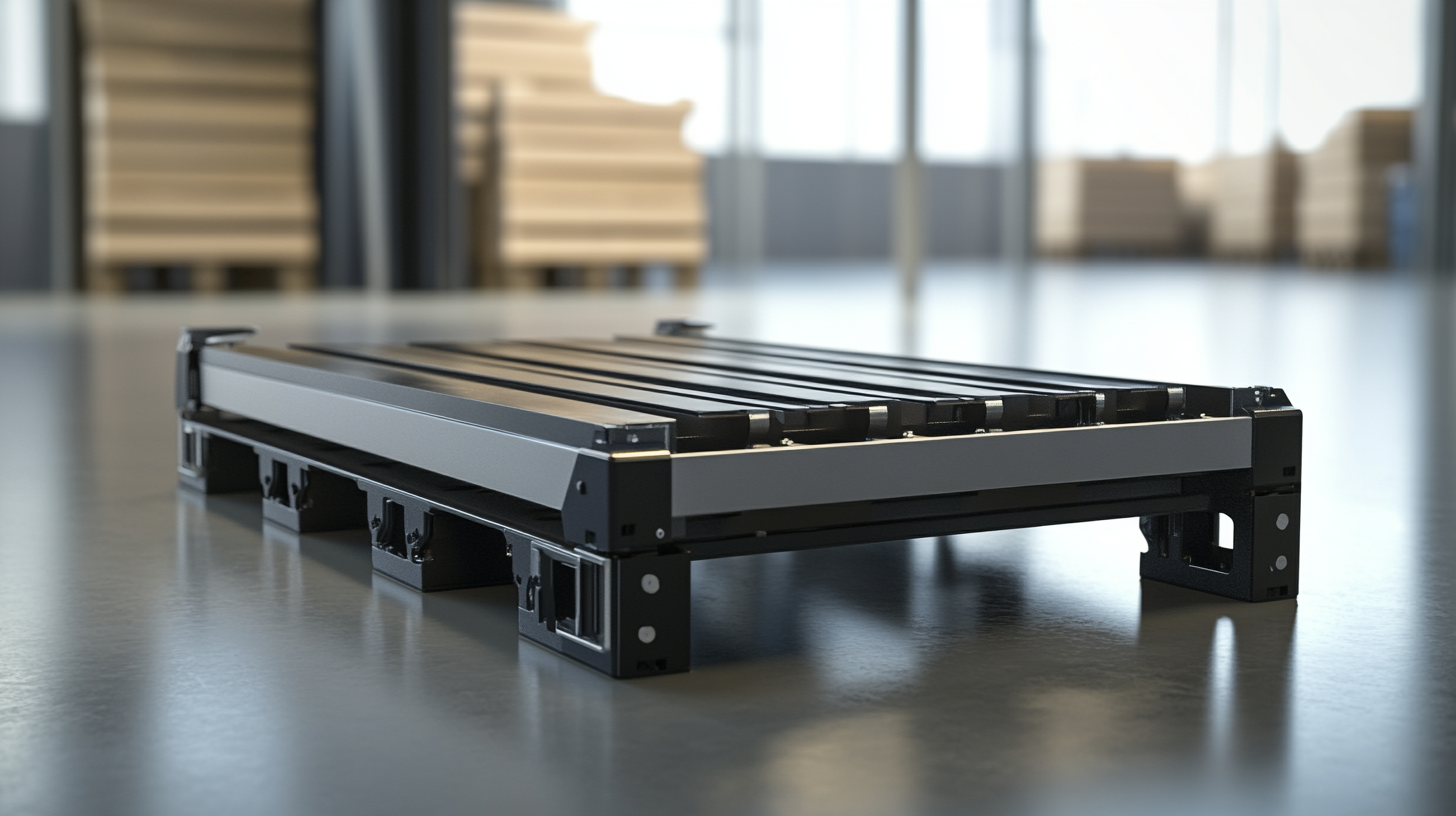

Their impact is far from overrated when it comes to automation in efficiency and contained productivity in the context of supply chains. The most important development of industry evolution is the advent of modern automated solutions, such as palletize machines, which significantly enhance operational efficiencies. The transition towards automation not only makes processes easier but also considerably reduces costs through the reducing factor of human errors and optimized resource allocation. Modern state-of-the-art pallet stackers are equipped with advanced technology to integrate seamlessly into existing supply chain frameworks, thus enhancing the overall throughput and productivity.

In addition, the rise of artificial intelligence has brought about a further transformation in many sectors. The enterprises nowadays have been using AI-enabled automation tools to replace menial tasks with machines, thereby allowing humans to spend their valuable time on more high-profile strategic tasks. In effect, such transfers have really boosted the productivity levels of most Fortune 500 companies, with quite a decent percentage of these revealing enhanced operational efficiency after applying AI in their managing supply chains. Automated systems make significant contributions both in agriculture and manufacturing toward addressing the human resource supply gap for sustainable practice.

The current advancement is going toward new paradigms for productivity, and these companies are indeed bringing new automation methodologies into their environments for competitive purposes. Automation, digital technology, and intelligent processes have pioneered dynamic changes in how supply chains are structured. The embrace of the new developments tends to improve productivity and give companies the tools to address the difficulties posed by a rapidly changing global marketplace. Such an environment will show the direction toward a trend that indicates an inevitability link between automation and efficiency as advantages reserved only for future winners.

Implementation of up-to-date palletizer systems comes associated with its very many challenges because of an ever changing global supply chain environment. The global palletizer market according to a report published by Grand View Research would touch $4.3 billion by the year 2027, with forces driving heightened demand automation across industries such as food and beverage, pharmaceuticals, and personal goods, and it said that harnessing the beauty of these advanced systems would be subject to overcoming many other hurdles-high initial investment outlay, needed skilled labor, and possible disruption during transitions.

First, upfront expenditure is one of the main drawbacks when an organization considers introducing sets of advanced palletiser systems in an industry. According to a study by Technavio, nearly 60 per cent of manufacturers opine that cost is a major initial barrier in automation. The benefits in the long run are great like efficiency and low labour costs, but the initial financial commitment is very unappealing to many organisations, especially smaller ones with low to medium turnovers. This calls for a strategic approach to budgeting, which includes financing options or phased implementation for gradual investment and adaptation.

Other prohibitive factors could also be the requisite of skilled labor to operate and maintain these advanced systems. The World Economic Forum estimated that in 2022, around 54% of all employees would require reskilling to some extent to meet the demands of the new technology. This indicates that training programs and collaborations with learning institutions are equally significant to ensure that the workforce has skills to handle advanced technology in palletizing automation. Therefore, successfully addressing these challenges would help to improve operational efficiency and result in a competitive advantage in a fast-paced marketplace.

In future development for stacking palletizer technology, a number of key trends are about to hit their respective transformations. The increased automation trend, through advancements in robotics and artificial intelligence, continues to be an active influence for enhancing efficiency and accuracy during palletization. The ability to integrate smart technologies allows for machine self-adjustment to various parameters in the shape and size of products thereby reducing downtime while improving throughput. This flexibility is key to manufacturers in satisfying the skyrocketing demand for customization in packaging.

Another trend is a movement towards sustainability of operations. Manufacturers today wish for palletizing systems that reduce waste and energy usage. Because new materials, especially eco-friendly ones and energy-efficient motors, are emerging and gaining acceptance, manufacturers are adopting greener ways. Sustainability not only helps to decrease the carbon footprint of such organizations; it also serves to attract eco-minded customers.

The Internet of Things (IoT) is actually defining a new future for stacking palletizers, taking them one step further-the connected assets capable of real-time monitoring and analytics. This connectivity enables user to track performance metrics, predict maintenance requirement, and optimize workflow toward greater productivity. Smarter and more interdependent stacking palletizer machines will become commonplace in the future as companies embrace these technological advancements across the realm of their supply chain ecosystem.

Stacking palletizer machines have evolved from manual operations to fully automated systems, beginning with mechanical automation in the early 20th century, which has paved the way for modern AI-equipped machines.

Innovations such as AI integration, IoT connectivity, and robotic automation have significantly enhanced efficiency and adaptability in logistics operations, allowing for better handling of products and waste reduction.

Companies such as Nolu股份, 机器人, 昆船智能, and 旷视 are at the forefront of innovations in the palletizer industry, showcasing advancements in AI-powered stacking machines and logistics solutions.

Automation improves operational efficiency by streamlining processes, reducing labor costs, minimizing human error, and optimizing resource allocation, leading to increased throughput and productivity.

AI enhances palletizers' capabilities by enabling intelligent sorting and stacking, automating routine tasks, and allowing human resources to focus on more strategic functions, which improves overall productivity.

The outlook is promising, with significant market growth expected as the integration of advanced technologies continues to streamline logistics processes and enhance responsiveness to global supply chain demands.

Digitalization integrates technologies like 5G to improve information flow and resource management, leading to resilient and secure supply chains that can effectively respond to disruptions.

Key benefits include the capability to handle a wider variety of products, optimizing warehouse space, reducing waste, and improving overall supply chain efficiency and reliability.

The evolution of stacking palletizers supports sustainable practices by fostering eco-friendly solutions in supply chains, essential for meeting growing environmental demands.

The convergence of automation, digital technology, and smart processes signifies a critical transition that enhances productivity and prepares businesses for the competitive challenges of a rapidly changing global market.