The Computer Numerical Control (CNC) Machines market is poised for growth driven by key factors such as the integration of artificial intelligence, strategic collaborations with technology partners, and a focus on addressing consumer adoption barriers.

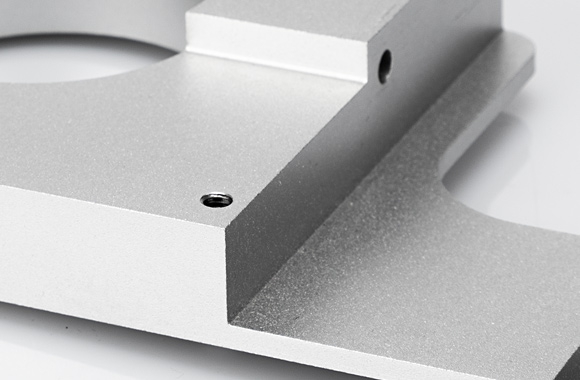

New York, Dec. 06, 2023 (GLOBE NEWSWIRE) -- Computer Numerical Control (CNC) Machines Market Overview: Cnc Machined Aluminium

The Computer Numerical Control (CNC) Machines market has witnessed significant advancements and growth in recent years, driven by the increasing demand for precision machining across various industries. CNC machines play a pivotal role in automating the manufacturing process, offering enhanced efficiency, accuracy, and flexibility.

The global computer numerical control (CNC) machines market is forecast to expand at a CAGR of 9.5% and thereby increase from a value of US$6.2 billion in 2023, to US$11.7 billion by the end of 2030. These machines are widely utilized for tasks such as cutting, milling, turning, and drilling, providing manufacturers with the capability to produce complex and high-precision components. The market is characterized by continuous technological innovations, expanding applications, and a growing emphasis on smart manufacturing solutions.

Global Market Growth Rate (CAGR 2023 to 2030)

By Type; By End Use Industry; By Region.

North America; Latin America; Europe; South Asia & Pacific; East Asia; The Middle East & Africa.

Hurco Companies Inc., Protomatic Inc., Metal Craft, AMS Micromedical LLC, JTEKT Corporation, Haas Automation, Fanuc Corporation, Siemens AG, DMG Mori Seiki Co.

The global CNC Machines market has experienced robust growth, propelled by the expanding adoption of automation in manufacturing processes and the quest for improved productivity. As industries worldwide increasingly prioritize precision engineering, CNC machines have become indispensable tools. The market's growth is also fueled by the integration of advanced technologies such as artificial intelligence and the Industrial Internet of Things (IIoT) in CNC systems. The aerospace, automotive, healthcare, and electronics sectors are among the key contributors to the market's expansion, with the Asia-Pacific region emerging as a prominent hub for CNC machine production and consumption.

Haas Automation, Inc.: Haas Automation stands as a leading player in the CNC Machines market, renowned for its cutting-edge machining centers and lathes. The company's commitment to technological innovation and precision engineering has solidified its position as a key provider of CNC solutions across diverse industries.

DMG Mori Co., Ltd.: A global powerhouse in the manufacturing industry, DMG Mori is a major player in the CNC Machines market. The company excels in producing advanced milling and turning machines, incorporating state-of-the-art technologies to meet the evolving demands of modern manufacturing.

Fanuc Corporation: Renowned for its expertise in industrial automation, Fanuc Corporation has a significant presence in the CNC Machines market. The company specializes in CNC systems and robotics, providing comprehensive solutions that enhance manufacturing efficiency and product quality.

Siemens AG: Siemens is a key player in the CNC Machines market, offering a wide range of solutions for precision machining. The company's CNC systems are known for their versatility and integration capabilities, catering to the diverse needs of industries worldwide.

Makino Milling Machine Co., Ltd.: Makino is a prominent player in the CNC Machines market, specializing in advanced machining centers and EDM (Electrical Discharge Machining) solutions. The company's focus on innovation and quality has positioned it as a reliable partner for manufacturers seeking cutting-edge CNC technologies.

Technology Trends in the CNC Machines Market:

The Computer Numerical Control (CNC) Machines market is witnessing transformative technological trends that are reshaping the landscape of precision machining. One of the key trends is the integration of Artificial Intelligence (AI) and machine learning algorithms into CNC systems. This infusion of intelligent technology enhances the machines' ability to adapt to varying production conditions, optimize toolpaths, and predict maintenance requirements, ultimately improving overall efficiency and reducing downtime.

Another significant trend is the rise of hybrid machining solutions, combining traditional subtractive manufacturing with additive manufacturing processes. This integration allows manufacturers to produce complex components with a high degree of precision and customization. Additionally, the incorporation of advanced sensors and Internet of Things (IoT) connectivity in CNC machines enables real-time monitoring, data analytics, and remote diagnostics, contributing to proactive maintenance and operational excellence.

Regulatory Landscape in the CNC Machines Market:

The CNC Machines market operates within a regulatory framework that aims to ensure safety, quality, and environmental compliance in manufacturing processes. Regulatory bodies, both at the national and international levels, set standards for CNC machine design, operation, and emissions. Compliance with these regulations is imperative for manufacturers to maintain product quality, worker safety, and environmental sustainability.

In recent years, there has been an increased focus on cybersecurity regulations as CNC machines become more connected and reliant on digital technologies. Ensuring the security of data, control systems, and communication protocols has become a priority to prevent unauthorized access and potential disruptions in the manufacturing process.

Consumer Trends in the CNC Machines Market:

Consumer trends in the CNC Machines market are heavily influenced by the broader shift towards smart manufacturing and Industry 4.0 principles. Manufacturers are increasingly seeking CNC solutions that offer ease of integration with other digital technologies, providing a seamless and interconnected production environment. The demand for user-friendly interfaces and intuitive programming features is also on the rise as manufacturers aim to streamline operations and reduce training times for machine operators.

Energy efficiency and sustainability have become prominent factors in consumer decision-making. CNC machines that incorporate eco-friendly features, such as energy-efficient motors and optimized cutting strategies, are gaining popularity. Additionally, there is a growing interest in modular CNC systems that allow for easy upgrades and customization, providing manufacturers with the flexibility to adapt to changing production requirements.

Consumer Adoption Barriers in the CNC Machines Market:

Despite the evident benefits of Computer Numerical Control (CNC) Machines in precision manufacturing, there are several barriers to consumer adoption that the industry faces. Cost remains a primary obstacle for many manufacturers, particularly small and medium-sized enterprises (SMEs). The initial investment required for CNC machines, coupled with ongoing maintenance and training costs, can be a significant financial burden. This cost factor often deters potential adopters, hindering the widespread integration of CNC technology in certain segments of the manufacturing sector.

Another barrier is the perceived complexity of operating and programming CNC machines. Traditional machining methods may be deeply ingrained in some manufacturing processes, and the transition to CNC machining requires retraining and upskilling of the workforce. The shortage of skilled operators who can effectively utilize CNC technology poses a challenge, as companies hesitate to invest without a skilled workforce to operate these sophisticated machines.

Regulatory compliance and standards also present hurdles in the adoption of CNC machines. Navigating complex regulations, especially in industries with stringent quality and safety standards, can slow down the adoption process. Additionally, concerns related to data security and intellectual property protection in the era of interconnected CNC systems may contribute to a cautious approach among potential consumers.

Future Outlook of the CNC Machines Market:

Looking ahead, the future of the CNC Machines market appears promising, with several trends shaping its trajectory. The ongoing advancements in automation, machine learning, and artificial intelligence are expected to further enhance the capabilities of CNC machines. Manufacturers can anticipate more user-friendly interfaces, intuitive programming tools, and adaptive control systems, addressing some of the current barriers related to complexity and training.

Moreover, the industry is likely to witness increased collaboration between CNC machine manufacturers and educational institutions to address the skills gap. Training programs and educational initiatives will play a pivotal role in preparing the workforce for the digital transformation in manufacturing, easing the transition to CNC technology.

As technology continues to evolve, there is a growing emphasis on sustainability and energy efficiency in manufacturing processes. Future CNC machines are expected to integrate eco-friendly features, optimizing energy consumption and reducing the environmental impact. This aligns with the broader industry trend towards sustainable and responsible manufacturing practices.

Collaborations and Partnerships in the CNC Machines Market:

Collaborations and partnerships play a pivotal role in shaping the dynamics of the Computer Numerical Control (CNC) Machines market. In recent years, the industry has witnessed a surge in strategic alliances between CNC machine manufacturers, technology providers, and research institutions. These partnerships aim to leverage complementary expertise, accelerate innovation, and address the evolving needs of the manufacturing sector.

Manufacturers are increasingly entering into collaborations with technology companies specializing in artificial intelligence, data analytics, and connectivity solutions. These partnerships facilitate the integration of cutting-edge technologies into CNC systems, enabling real-time monitoring, predictive maintenance, and enhanced automation. Such collaborations contribute to the development of smarter, more efficient CNC machines that align with the principles of Industry 4.0.

Additionally, collaborations between CNC machine manufacturers and educational institutions are fostering the creation of training programs and curriculum enhancements. These initiatives aim to bridge the skills gap in the workforce, ensuring that operators are well-equipped to harness the full potential of CNC technology. By fostering stronger ties between industry and academia, these collaborations contribute to the cultivation of a skilled workforce ready for the digital era of manufacturing.

Conclusion and Recommendations for the CNC Machines Market:

In conclusion, the Computer Numerical Control (CNC) Machines market is poised for significant growth and transformation. The integration of advanced technologies, strategic collaborations, and a focus on addressing adoption barriers are key drivers shaping the industry's future. As CNC machines become more intelligent, connected, and user-friendly, their application across diverse manufacturing sectors is likely to expand.

To capitalize on the opportunities presented by the evolving CNC Machines market, manufacturers should prioritize strategic collaborations with technology partners. These partnerships should aim to incorporate emerging technologies, enhance machine capabilities, and stay ahead of industry trends. Moreover, fostering collaborations with educational institutions will be crucial for addressing the skills gap and ensuring a proficient workforce capable of maximizing the benefits of CNC technology.

In light of the growing emphasis on sustainability, CNC machine manufacturers should explore partnerships that focus on eco-friendly solutions. Research and development efforts aimed at optimizing energy efficiency, reducing environmental impact, and implementing sustainable manufacturing practices will be essential for long-term success.

Business intelligence is the foundation of every business model employed by Persistence Market Research. Multi-dimensional sources are being put to work, which include big data, customer experience analytics, and real-time data collection. Thus, working on “micros” by Persistence Market Research helps companies overcome their “macro” business challenges.

Persistence Market Research is always way ahead of its time. In other words, it tables market solutions by stepping into the companies’/clients’ shoes much before they themselves have a sneak pick into the market. The pro-active approach followed by experts at Persistence Market Research helps companies/clients lay their hands on techno-commercial insights beforehand, so that the subsequent course of action could be simplified on their part.

Email: sales@persistencemarketresearch.com

Cnc Machining Industries Web: https://www.persistencemarketresearch.com